Technologies

Deep print printing – rotogravure

Rodata has 6.8 and 10 color rotogravure printing machines, respectively, of high capacity, capable of printing a wide range of plastic or paper media.

Production of “sleeve” labels

Rodata produces “sleeve” labels on its own technology line for many customers in Romania and Europe. By using Rodata, you benefit from the expertise and experience of a team of specialists who assist you step by step and answer all your technical questions, helping you design the graphics and adjust the equipment.

Embossing and embossing

Embossing is a process of ennobling the label by highlighting certain details of it, thus creating a special bas-relief effect.

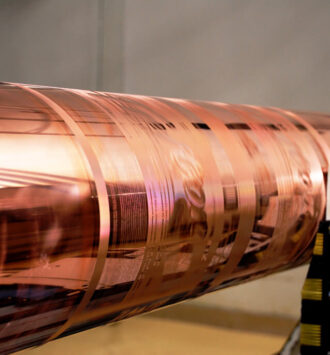

Engraving the cylinders

To reduce the costs of packaging and labels, go to Rodata! We have our own galvanoplasty line for the production and engraving of cylinders used in the label printing process.

Lamination

Rodata has technology for laminating films in a wide range of combinations: Paper + aluminum, paper + OPP (transparent, opaque, metallic), paper + PET (transparent, metallic), OPP + aluminum, OPP + paper + OPP etc. Lamination is done both for aesthetic reasons and for product safety, being able to provide various barriers to protect the product and maintain its characteristics (protection against light, oxygen or vapor barrier, etc.).

We have the following processing technologies:

- High capacity rotogravure printing machines capable of printing a wide range of supports (polypropylene, polyester, polyvinyl chloride, polyethylene, polyamide, polyamide, polyvinyl chloride) cellophane, paper, other laminates);

- Digital printing machine capable of printing a large number of colors on various types of plastic and paper support: white, transparent, metallic;

- machines for laminating films (duplex or triplex) solvent-based solvent and solvent based in a wide range of combinations: paper + aluminum, paper + plastic (transparent, opaque, metallic), paper + polyester (transparent, metallic), polypropylene + aluminum, polypropylene + paper + polypropylene;

- machines for the production of shrink and stretch sleeves made of polyester, polyethylene and polyvinyl chloride, both in rolls and individually cut;

- Plastic and paper burrary machine, this process offers the possibility of ennobling the label by highlighting certain details of it, thus creating a special bas-relief effect;

- cutting machines in rolls and sheets

- Machine for laying hot melt glue and wax on one or two sides;

- Galvanizing line;

- Cylinder engraving line

- Cylinder sanding line

- Printing control machine for checking the quality of the cylinders and the pattern on various supports after engraving the cylinders;

- Finish line labels composed of: sheet cutting knife, vacuum machine (aeration and topping), sheet counting machine, guillotines, stamping lines (manual, automatic and for sticker labels) various shapes and sizes, bandage machine (sheet packaging);

- Automatic ink preparation and dosing station, with computerized setting of color recipes and the possibility of checking them with the help of spectrophotometer;

- Laboratory quality control raw materials and products

In order to differentiate ourselves from other suppliers, we provide our clients with complete pre-press services, technical support, packaging consultancy, integrated production and logistics. We have a customer service available and our packaging engineers can successfully design any solution for optimization, rationalization, replacement, dedicated packaging development, environmental impact reduction, cost reduction.